Vehicle workshop projects rarely drop into ones lap. They are hard earned. Price alone, although a factor for the client to consider is not always the decision maker or breaker.

One such project in question was won not only competitive fitness, but design and Project Management. The client, Robins & Day. Their project, Peugeot Citroen, Chingford Road, Walthamstow, East London. Three years in the planning, 26 weeks in the making. It wasn’t all plain sailing; there were many engineering challenges with building a flagship dealership in East London.

From the outset, meetings with the client and the Architect were key factors in identifying servicing volumes, expected repair works undertaken and the level of service and products that our client wanted to offer and provide to their customers. These factors and more became the framework that the building would eventually be designed around. Throughout the pre-build stage it was necessary to meet with the client’s principal contractor in order for them to understand our engineering requirements in delivering what has become a centre of excellence for Peugeot Citroen.

Building on ground with a high water table and land that historically has seen flooding dictated that the support frame work would be piled with an elevated ring-beam that would support the floor. Additional steel work would be hung from the ring-beam to enable the forming of recesses to house scissor platforms, four post platforms for the MOT area as well as Brake Test Beds with integrated suspension testers.

To meet building regulations for carbon offset, two plinths of reinforced concrete were formed within the vehicle workshop, both one metre wide running the entire length. This gave us the engineering that we needed in order to secure our two post lift arrangement. The remainder of the floor could then receive insulation and be finished with a fibre mesh floor screed. Thus meeting our engineering needs and the need for the building to meet carbon off setting. Deep into the construction programme it was essential to manage our works daily. With extensive ground works ongoing on the outside the challenge became coordinating delivery opportunities in which to off load vehicle lifts and place in situ.

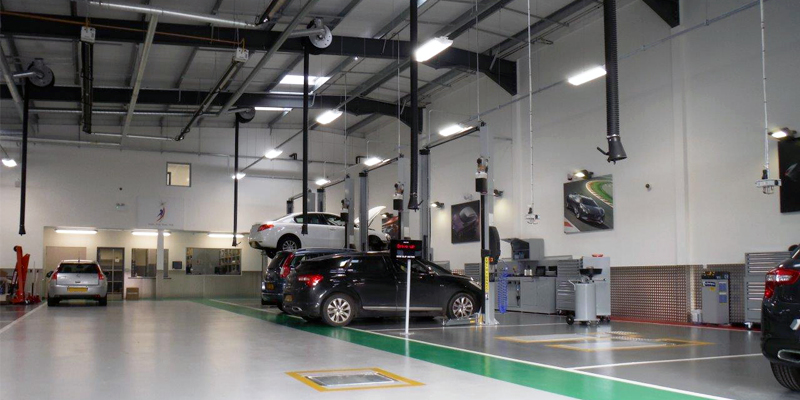

The main workshop design centred around eight x 4 tonne, two post hydraulic Rotary lifts which was complemented by a further two x 5 tonne two post hydraulic lifts. To give Peugeot Citroen a wide scope of vehicle lifting capability the inclusion of two x 3 tonne recessed scissor platforms was also added. The dedicated tyre changing and wheel balancing bay received its own mid-rise scissor platform there by completing the versatility and flexibility that was needed for the right now and well into the future. Each Rotary vehicle lift was selected for its “In-Bay” design. This allowed compressed air to be routed directly inside one of the columns. This design also included the facility to route electrical power in the same fashion. A unique and ergonomic solution to negate trailing leads therefore removing trip hazards.

Our design didn’t stop at the main workshop. A separate MOT area comprising of dual class 7 ATL was also part of this stunning workshop. Working with the principal contractor and the Architect, the engineering was created to recess two x 5 tonne 4 post platforms. Class 7 Brake Test Beds with integrated suspension testers. With the addition of recessed side slip detector plates the two MOT lanes didn’t look as though they were just supplied, they looked, designed to be supplied. Dual monitors in each lane increased the functionality and ergonomic operation of this MOT area.

Since 2001, we’ve strived in offering our clients a complete corporate image throughout the workshop. Back of House, front of house, in their very description divides a successful dealership. We believe in one team, working in one building under one roof. The whole dealership should be seen as front of house. We therefore put a cabinetry design on the table that was affordable, that met the Technicians requirements for safe and adequate storage of hand tools, which offered bulk storage and that also, housed the items that are required for every day servicing. Each Technician’s bay became a uniformed corporate image. With the correct oil monitoring system integrated within the cabinet design every aspect of the working day can be managed from workshop control.

We were delighted with the positive response we received from Peugeot SA. Working on this project was challenging but also a pleasure. Design and Project Management are key features in delivering affordable new build projects or indeed refurbishments. Combine these two key features with excellent industry recognised products and the results speak for themselves.

Don’t ask your equipment supplier to supply, ask them to design, supply and project manage. That’s what we do here at T.R Bullworthy Ltd.